A Deep Dive into the Working Mechanism of Luffing Jib Tower Cranes

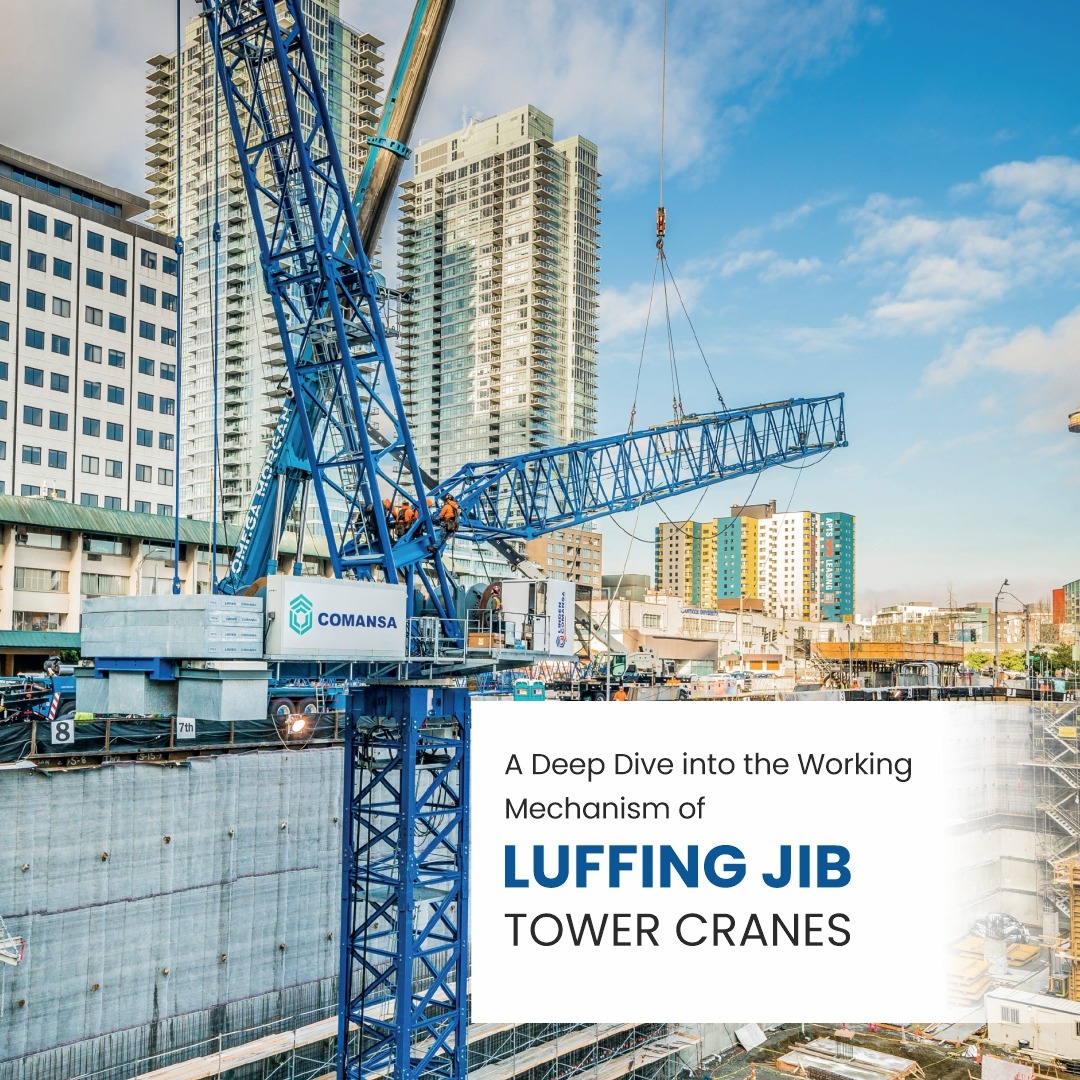

In the ever-evolving world of construction, the demand for smarter and more space-efficient machinery has led to the rising popularity of luffing jib tower cranes. Known for their ability to operate efficiently in tight urban environments, these cranes offer a unique advantage over traditional tower cranes. But how exactly do they work? Let’s dive into the fascinating mechanism behind luffing tower cranes and understand what makes them an essential part of modern construction projects.

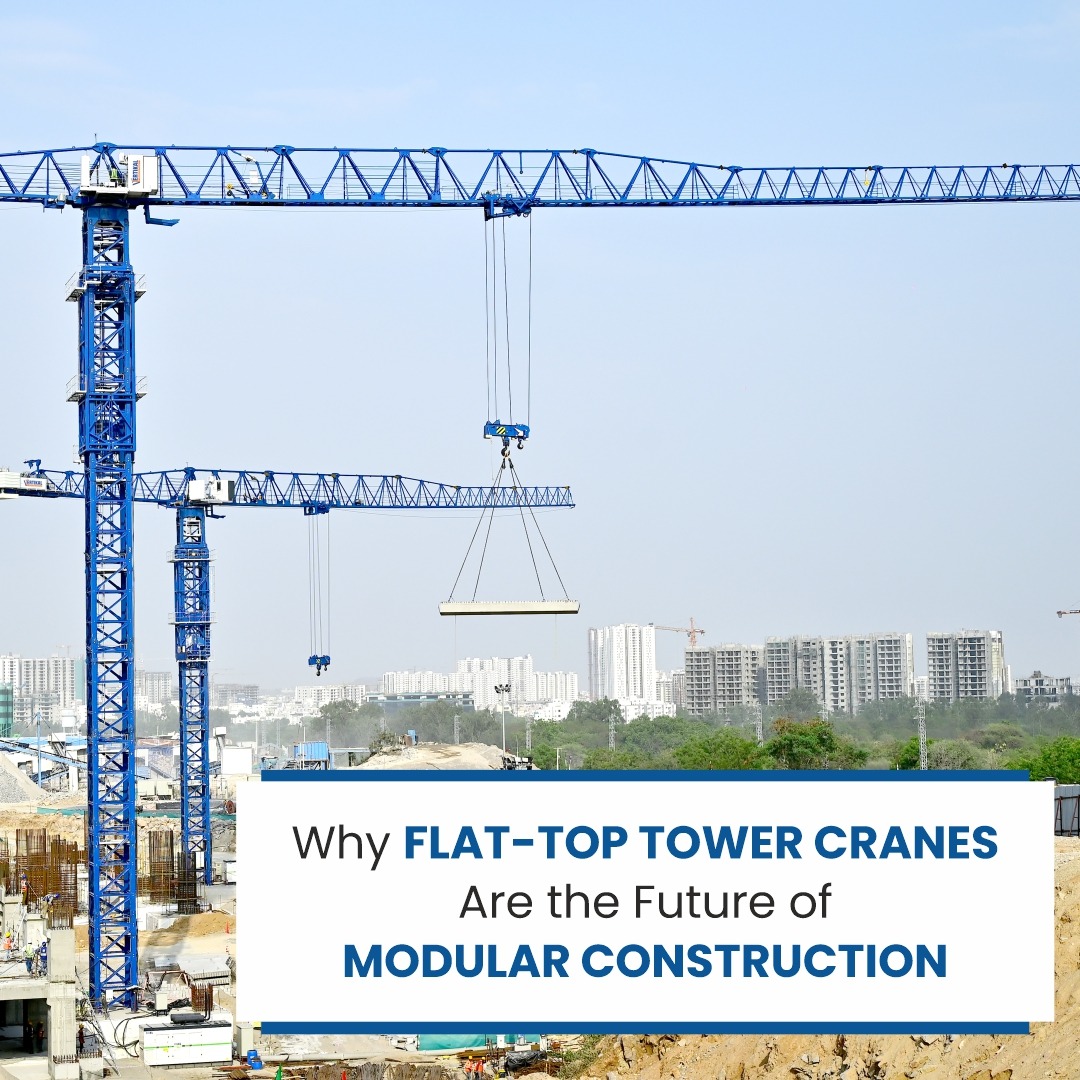

What Is a Luffing Jib Tower Crane?

Before we get into the mechanics, it’s important to understand what a luffing jib is. Unlike flat-top or hammerhead cranes with fixed horizontal jibs, a crane luffing jib can move up and down, allowing the operator to “luff” or pivot the jib to different angles. This flexibility is what sets luffing jib tower cranes apart, especially in projects where space is at a premium.

How Does a Luffing Tower Crane Work?

The working mechanism of a jib tower crane with a luffing jib is a blend of engineering precision and smart control systems. Here’s how it functions:

1. Luffing Motion

At the heart of the luffing tower crane is the jib’s ability to move vertically. Using a hydraulic or cable-operated luffing mechanism, the jib can raise or lower to avoid obstacles, operate near existing structures, or work alongside other cranes without interference. This ability to adjust the jib angle is crucial in congested urban projects where overlapping swing paths can be dangerous.

2. Load Lifting and Movement

The hoisting mechanism, typically located on the tower or rear platform, raises and lowers loads via a wire rope system. Since the luffing jib doesn’t extend as far horizontally as other cranes, the load radius is usually shorter—but it makes up for it in vertical precision and control.

3. Counterweights and Stability

To maintain balance, luffing jib tower cranes use heavy counterweights, usually at the rear end of the crane. These counterweights shift the center of gravity and ensure stability even when the jib is luffed at steep angles.

4. Compact Slewing Radius

One major advantage of a crane luffing jib is the reduced slewing (rotating) radius. This allows the crane to operate efficiently in compact zones where traditional tower cranes may not fit or may pose safety risks due to their wide swings.

Benefits of Luffing Jib Tower Cranes

1. Ideal for Dense Urban Construction: Minimal swing area means they can work close to other cranes or buildings. 2. Enhanced Safety: Controlled jib movement reduces collision risks. 3. Efficient Load Handling: Better suited for tall buildings where vertical reach matters more than horizontal span. 4. Great for Restricted Sites: Easily navigates obstacles like adjacent high-rises or power lines.

When Should You Use a Jib Tower Crane with a Luffing Jib?

Luffing jib tower cranes are ideal for: 1. High-rise construction in city centers 2. Projects with multiple cranes on the same site 3. Sites with limited horizontal space but significant vertical demand Whether you’re planning a skyscraper or a tight-site renovation, understanding how these cranes work will help you choose the right equipment and optimize your construction workflow.

Conclusion

The sophisticated engineering behind luffing jib tower cranes makes them indispensable for modern construction. With their vertical lifting prowess, minimized swing radius, and adaptability in confined spaces, they are the go-to solution for complex, high-density projects. If you're exploring luffing tower crane solutions for your next job site, understanding the mechanism is the first step toward smarter, safer, and more efficient lifting operations.