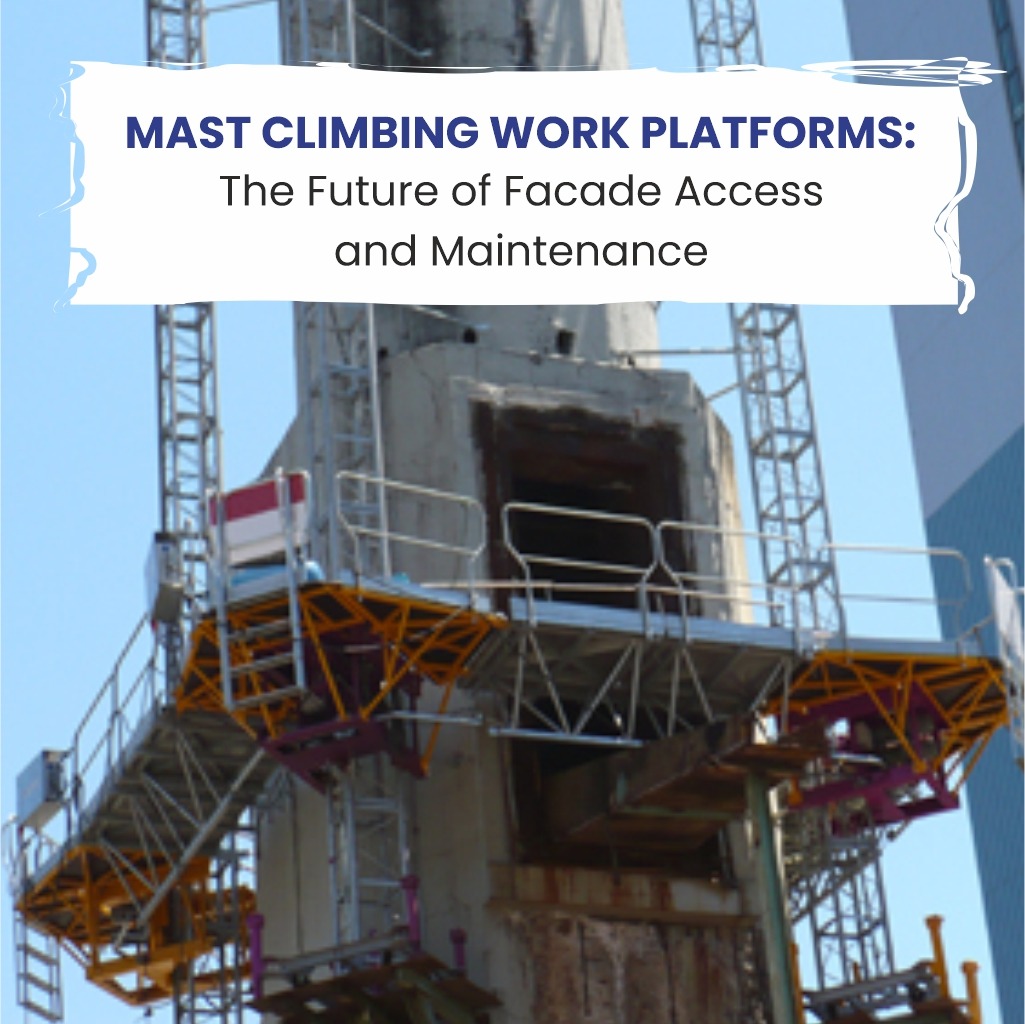

Mast Climbing Work Platform: The Future of facade access and maintenance

The Spark: A Real Question, A Real Challenge

Imagine a busy renovation project in a growing city—let’s call it Cityscape Towers, a 12‑storey rental building in mid‑construction. One morning, the site manager, Meera, paused by the façade and muttered, “We’re losing hours every day just setting up and shifting scaffolding across different levels.” Materials stacked, teams standing idle—every elevation change meant more labour, more time, more cost.

Then Meera suggests: why not try a Mast Climbing Work Platform (MCWP)? Could this cutting‑edge alternative to scaffolding solve her problem? The answer wasn’t just yes—it was transformative.

This is not a fictional fantasy—it echoes the real shift sweeping modern construction and renovation. Today, MCWPs are reshaping how facades are accessed, safely maintained, and built.

What Is an MCWP — In Plain Terms

A Mast Climbing Work Platform is a powered platform that climbs a rigid vertical mast. It carries workers, tools and materials, rising and descending with buttons—rather than ladders, ropes, or step‑by‑step scaffolding erection and dismantling.

Key realities about MCWPs:

- Built to comply with international safety standards (e.g. EN 1495+A2, BS 7981:2017)

- Operated using rack‑and‑pinion or similar drive systems, with redundant motors or emergency brakes to prevent overspeed descent

- Available in single‑mast and twin‑mast configurations; platform widths up to tens of metres, lifting heights up to 100 m or more

Why They Outpace Scaffolding: Speed, Safety & Savings

- Speed of Installation & Mobility

MCWPs can be set up and repositioned far more swiftly than traditional scaffolding. With fewer components, modular masts, and motorized movement, the time to begin façade tasks is dramatically reduced. This translates into fewer labour hours, faster progress, and more predictable schedules

- Safety Built‑In

Platforms come with integrated guard‑rails, anti‑fall emergency stops, overload sensors, and mechanical brakes. Because they move as a single unit, there’s minimal climbing or improvising on unsafe levels. Proper inspections, maintenance and user training are mandated to avoid rare—but serious—failures

- High Payload & Ergonomics

MCWPs can transport heavy materials—sometimes several tons—alongside teams of workers on one stable platform. That avoids multiple trips, awkward carrying, or balancing on narrow planks. Workers can operate at a comfortable height, reducing strain and enhancing productivity

- Space & Visual Efficiency

Unlike scaffolding, MCWPs take less ground space and don’t obstruct the building façade when not in use. This is especially valuable in busy urban sites or residential projects where sightlines and access matter

- Cost‑Effectiveness Over Time

Although the initial capital or rental cost can be higher than scaffolding, time savings, reduced labour, less rework, and increased efficiency often lead to overall lower project costs—especially on multi‑storey or multi‑phase façade jobs

Versatility: From Masonry to Modern Cladding

MCWPs have spread well beyond high‑rise brickwork. Example uses include:

- Masonry, plastering, and insulation

- Curtain wall/glazing and metal panel installation

- Painting, façade coatings, repairs and historic restoration

- Specialized industrial or infrastructure facades (chimneys, cooling towers, nuclear facilities)

Their modular nature means you can configure platform shape, width, length, even around curves or corners to suit architectural complexity (as with Alimak MC 650, GEDA MCP 1500, or Fraco ACT‑8 formats)

The Story Continues: Cityscape Towers Revisited

Returning to Meera’s project: once the MCWP arrived, the platform rose alongside the building façade, tools and brick stacks on deck. Workers shifted levels with a button press, not with dismantling scaffolding. The team finished window installation on level 5 in one afternoon—time that would have been spent re‑erecting scaffold sections.

Best of all: building residents didn’t see tarpaulin everywhere. Light remained in apartments. Neighbours weren’t disturbed by constant scaffolding noise.

Pre‑ and post‑task training and inspection ensured proper use. Emergency brake systems were tested. The system had a mechanical overspeed fail‑safe to prevent uncontrolled descent—in line with BS 7981 and EN 1495 standards

What You Must Ensure Before Deploying MCWPs

- Certification & Inspection

Ensure the MCWP adheres to relevant standards (EN, BS, ANSI) and has been inspected by qualified personnel. - Operator Training

Users should receive model‑and‑site specific training, awareness of hazards, emergency procedures and load limits - Load & Brake Safety Check

Confirm mechanical brakes and motors are configured to halt descent at ≤ 0.4 m/s, and malfunction detectors are active - Anchorage & Structural Fit‑Out

A qualified engineer must design mast ties, foundation, and anchorage systems so platforms stay securely aligned with the façade. - Maintenance & Planning

Regular functional checks, planning of safe dismantling, and clear protocols for overhead wind or severe weather conditions.

The Future Outlook: Why MCWPs Are the Next Norm

- Demand Surge: Global uptake is growing, especially for complex façade geometry, restoration tasks, and high‑efficiency urban projects

- Technological Evolution: Greater payload capacities (up to 8 tons or more per mast), faster speeds (9 m/min to ~39 ft/min), and easier modular reconfiguration make MCWPs more flexible than ever

- Integrated Value: MCWPs can be combined with material hoists, cranes, hoisting accessories to create tailored vertical access ecosystems—ideal for modern, tight‑schedule construction.

- Industry Pressure: Safety focus and regulatory updates continue improving manufacturer and user protocols. Regions with strict rules (UK, Canada, EU) show better safety outcomes once MCWP standards are fully implemented.

Final Thoughts: A Smile on the Façade

Meera’s site delivered the renovation weeks ahead of time, with fewer site disruptions, better quality results and cost savings. The MCWP had offered a safer, faster, more flexible way to work on the façade.

By choosing Mast Climbing Work Platforms, project teams gain:

- A fast, precision vertical access solution

- Enhanced safety for workers and reduced risk of musculoskeletal strain

- Lower project costs through streamlined labour and setup

- Versatility to handle everything from brick to curtain wall to painting

- Space‑efficient deployment friendly to cityscapes and residents