Behind the Design: What Makes Flat Top Tower Cranes the Engineers favorite?

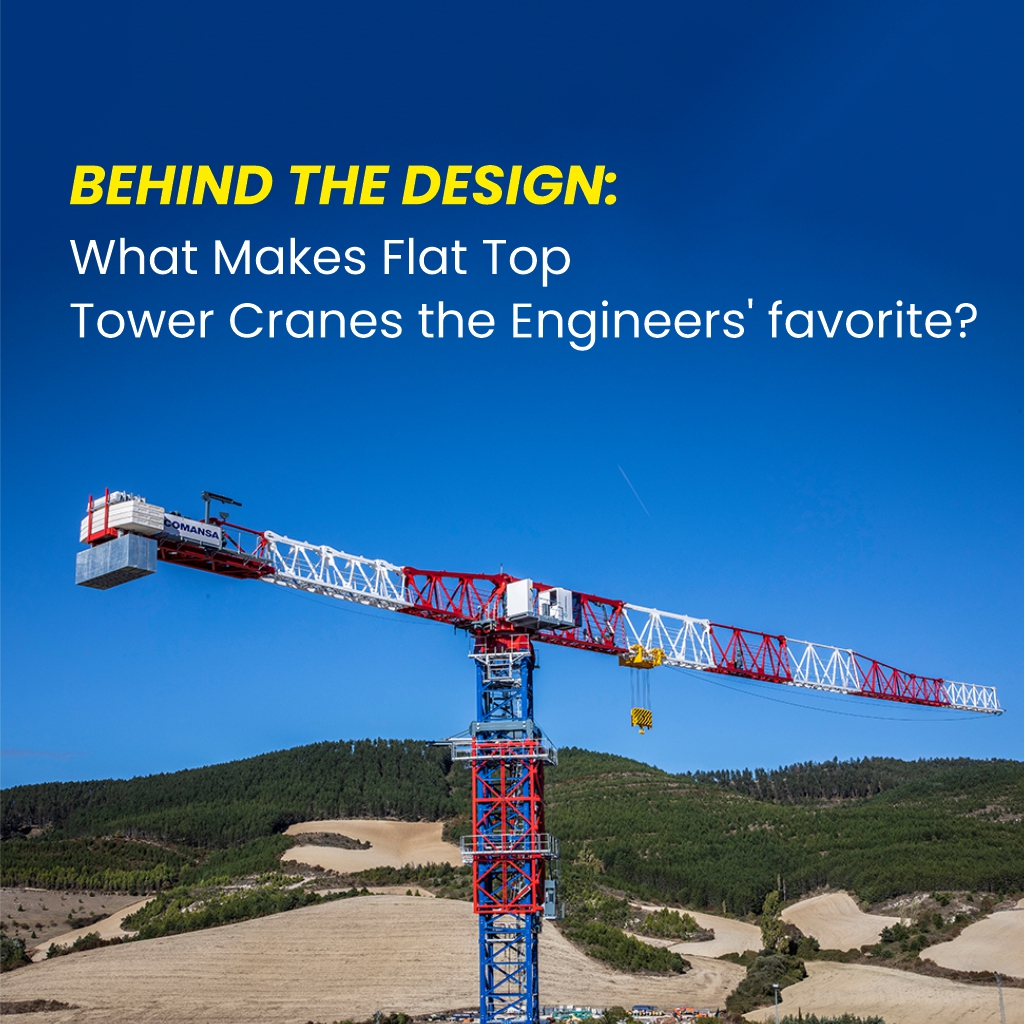

In the fast-evolving world of vertical construction, flat top tower cranes have become more than just equipment — they are the workhorses that define modern skylines. While many might see cranes as just towering machines of steel and cables, engineers and construction veterans know better. Behind their clean silhouette lies a combination of precision design, modular thinking, and operational intelligence that makes flat top tower cranes an industry favorite.

In this blog, we unpack the design philosophy, real-world benefits, and field-tested reasons why flat top tower cranes have earned such a strong reputation among engineers.

1. The Genius of the Flat Top Design

At first glance, the absence of the traditional apex or “cat head” makes the flat top crane look sleek — but that design decision is far from cosmetic.

Modular Assembly Means Faster Setup

The flat top design simplifies the assembly process. Without a top-mounted jib tie-bar, the crane can be erected more quickly and safely in tight job sites, reducing costly downtime. For engineers, this translates to tighter schedules and more responsive site operations.

Enhanced Component Interchangeability

Flat top cranes are built with modularity at their core. Jib and mast sections are often interchangeable across models, streamlining fleet management and reducing the need to stock a wide range of spare parts — a real win for logistics and inventory planning.

2. Site Flexibility in Congested Environments

Urban construction sites often resemble giant puzzles. The flat top tower crane fits right into that narrative — offering flexibility and safety in tight spaces where multiple cranes must operate simultaneously.

Overlapping Jibs Without Interference

Unlike hammerhead cranes with a protruding apex, flat top tower cranes allow for overlapping jib operations. This is a game-changer on congested job sites, minimizing the risk of crane-to-crane collisions.

Reduced Climbing Height

The absence of a tower top enables easier over-jib climbing, requiring less height to begin with — especially valuable in projects with height restrictions or phased development.

3. Safety by Design

Every element of a flat top tower crane is engineered with safety in mind.

Lower Wind Load Impact

Flat top cranes generate less wind resistance due to their streamlined structure. This means more stability, safer operations in high-altitude zones, and fewer weather-related stoppages.

Simplified Maintenance

From hoisting winches to slewing gearboxes, the accessibility of key components makes inspections and repairs easier and faster — directly reducing crane downtime and increasing on-site safety.

4. Operator Comfort and Precision Control

Experienced crane operators often speak of flat top cranes with a certain reverence. The design not only optimizes the crane’s physical form but also prioritizes control and comfort.

Smooth Load Handling

Modern flat top cranes are equipped with intelligent load-moment indicators and variable frequency drives that ensure smooth and precise movements — reducing operator fatigue and increasing efficiency.

Ergonomic Cabs

The latest models feature panoramic cabins, climate control, and intuitive controls — small features that lead to big improvements in operator performance and safety.

5. Trusted by Engineers Across the Globe

Whether it’s high-rise residential towers in Mumbai, commercial hubs in Dubai, or infrastructure projects in Singapore, flat top tower cranes are consistently chosen by engineering teams aiming for reliability, speed, and scalability.

Case in Point: Modular Projects

In modular construction, where precision and timing are critical, flat top cranes allow engineers to plan with minimal vertical clearance — making them ideal for lifting pre-fabricated units or modular pods with accuracy.

Final Thoughts: A Crane that Thinks Ahead

Flat top tower cranes aren’t just a smart evolution in crane design — they’re a thoughtful response to the changing needs of construction engineers. They offer a rare blend of form, function, and foresight — a trio that’s hard to beat in any industry.

For engineers, project managers, and equipment planners alike, the flat top tower crane isn’t just a tool. It’s a strategic asset — designed for the complexity and pace of today’s building world.

Got insights from the field?

We’d love to hear your experiences working with flat top tower cranes. Share your thoughts in the comments or reach out to our team at Vertikal.in — where innovation meets elevation.